Digital Alloys’ Guide to Metal Additive Manufacturing - Part 2

Application Criteria

November 30th, 2018

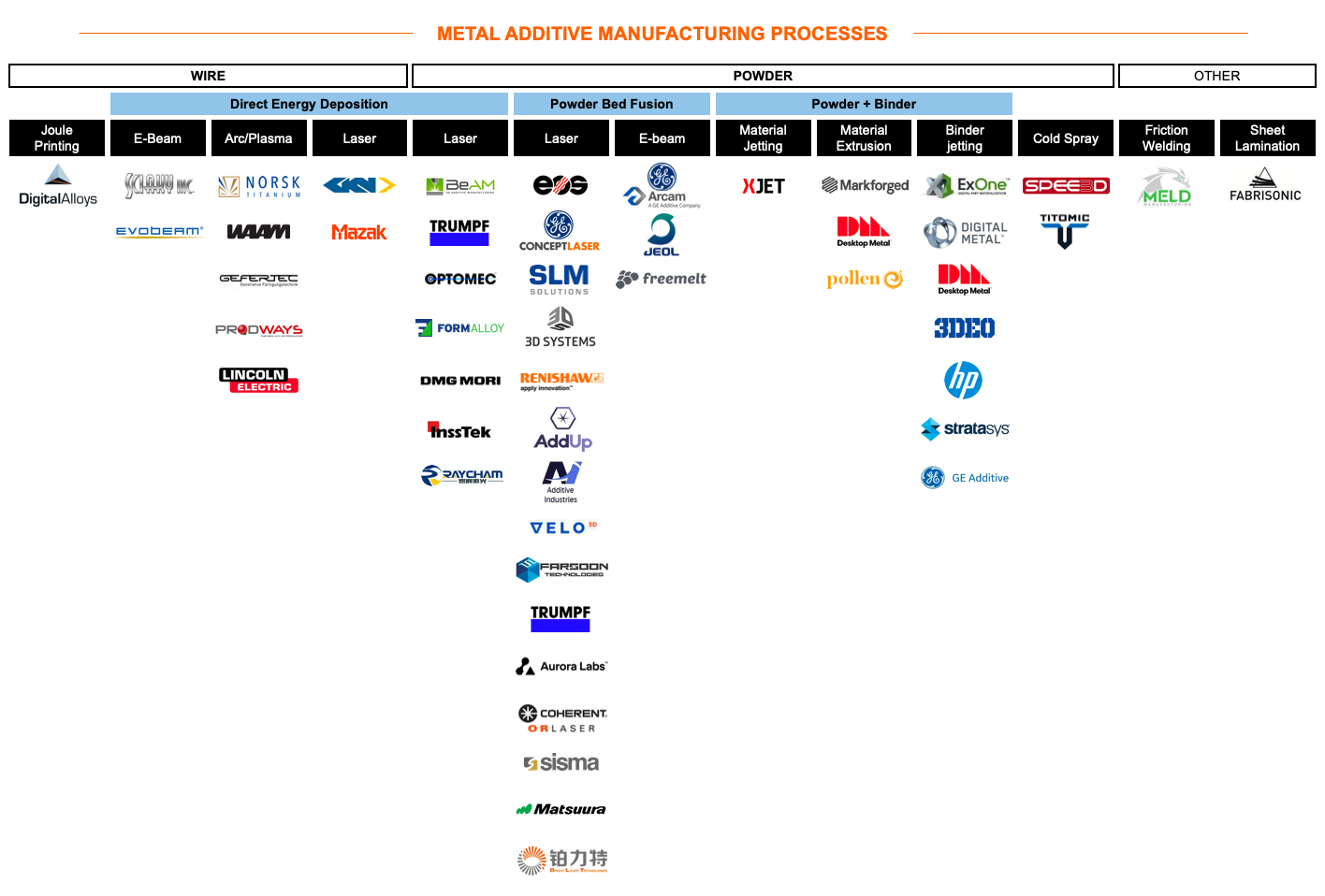

There are over a dozen unique Metal Additive Manufacturing (AM) (aka 3D Printing) technologies available today. How do you pick the best solution?

In our first blog post, “The Business Value of Metal Additive Manufacturing”, we discussed how to find the highest value applications for metal 3D printing. In this second post, we define application requirements in a way that easily maps to the capabilities of the various metal AM technology options.

As is true for any manufacturing process, each metal AM technology has its own set of capabilities, strengths, and weaknesses which dictate when and where it is useful. Applications for metal AM have specific requirements. Using a structured framework helps determine whether these requirements can all be met by a particular technology. Application criteria to consider when selecting a metal AM technology are listed in the table below. We then detail each criteria.

Production Speed and Cost

Production Speed

A manufacturing technology is viable only if its throughput can keep up with demand. Using metal AM to directly print end-use parts can eliminate long tooling lead times but the eventual production capacity of the process must meet requirements. Some solutions dictate adding multiple printing units to scale capacity. In these scenarios, the total cost of adding each unit (including the costs of equipment, facilities, labor, and qualification) should be considered.

Print time per part is typically the first consideration, but it is only one piece of the total manufacturing workflow. All the pre- and post-processing steps (the topic of our next blog post) must be considered to identify bottlenecks in the end to end process and determine potential throughput. Metal printing processes have a huge range in production speed but OEM claims are often a best-case-scenario so a print time estimate should be used that is accurate for the specific application.

Production Cost

Experts cite the cost of metal AM as the largest reason it hasn’t seen greater adoption. In assessing costs of metal AM technologies, all production inputs need to be considered. These include facility and equipment costs (printer, pre- and post-processing equipment, facility overhead), materials, and labor through all steps of the production process. When all of the associated costs are amortized across the production volume, the unit economics must meet the requirements of the program. This is not to say the lowest cost technology is always the best option, but if metal AM is more expensive than conventional processes then this must be outweighed by value added through improved product performance, time savings or elsewhere. (We will provide detailed costing calculators and overview of all the steps in an AM production process in future blog posts).

Materials and Properties

Material Availability and Compatibility

In many applications, materials have already been validated and qualified. Selecting technologies that can print the same specific grade of metal in use today (e.g. Titanium Ti-6Al-4V) is a good way to narrow the list. Powder based processes are limited by the types of metals that can be processed into powder and also metallurgical limitations of the sintering process. Wire based processes tend to be compatible with a wider range of material options and many use standard welding wire which is already manufactured in thousands of different grades of metals. Metal AM technology providers will advertise which materials are available with their systems today.

Multi-metal printing, the ability to combine different metals in a single printed part, has potential to achieve breakthrough performance and functionality over single metal parts. Some metal deposition approaches have, or will soon add, this capability.

Mechanical Properties

Just choosing the right material isn’t enough. There are many material properties that are critical to performance and safety. Print-process dynamics such as heat loading and cycling, layer to layer bonding, etc. can greatly influence the final material properties and the directionality and consistency of those properties. Properties that are commonly used to define application requirements include: yield strength, ultimate tensile strength (UTS), elongation at yield/break, impact strength, shear strength, and fatigue strength. Many companies will need to do their own extensive material level testing before moving to a part level testing program but vendor data is a good place to start comparing technology solutions against your application requirements and against each other. It is important to note that, for some 3D printing processes, material properties vary with the size, thickness, shape, and print-orientation of the printed part.

Even for the exact same material, different printing processes can yield vastly different material properties. The properties critical to the application must be understood so that an appropriate testing plan can be developed and a metal AM technology selected which can deliver them.

Density

Density, although highly correlated to the above mechanical properties, presents additional considerations for functionality like sealing and bearing surfaces. The density, and more specifically, porosity near the surface of the part, will limit what surface smoothness is achievable from secondary operations such as milling, grinding, and polishing (see the “Resolution” section below). Many metal AM technologies require time consuming and costly post-processing in order to achieve high densities.

Consistency

Measuring good material properties is only truly useful if these properties are uniform throughout the part (homogeneous & isotropic) and repeatable from part to part. Metal AM providers are being pushed by industry to be more transparent about actual yields, and most customers with high quality requirements are doing their own testing to ensure that the variations within parts, from part to part, build to build, and machine to machine are acceptable for the application.

Part Specifications

Accuracy and Repeatability

Accuracy and repeatability are complex topics because many metal AM processes contain many sources of variation that are hard to control. In addition, it is not always easy to know when as-printed parts require high accuracy since secondary operations are often used to achieve critical tolerances and surface smoothness. Printing accuracy is most important for surfaces that are hard to reach for secondary operations (e.g. internal features). Dimensions and surfaces which are critical to the application must be identified. Then, based on the geometry, it can be determined which are achievable with post-processing and which are requirements for the as-printed part.

Resolution

Process resolution limits both minimum printed feature size and surface smoothness. In the case of metal AM, resolution is usually defined by voxel (3d pixel) size, or more explicitly the length, width and height of a discrete element. In powder bed and deposition processes the bead width and layer height are the two key measures of process resolution. Just like for accuracy requirements, surface finish and minimum feature size requirements must be analyzed across the entire part and compared to technology capabilities to see what can be achieved in the as-printed state vs through secondary operations. Secondary operations can smooth surfaces and add fine features, but only when the appropriate regions of the part are accessible. Additional costs and time of secondary operations must also be considered.

It is important to note that no metal printing technique today can produce a functionally “smooth surface” of the type required for any bearing, sealing, or tightly mating surfaces. Regardless of the 3D printing process, most features and surfaces with critical tolerances and smoothness requirements need to be achieved with finish machining.

Part Size

Part size can be another quick way to filter technologies for applicability. Two important factors help determine feasibility of a specific application: longest part dimensions (build envelope) and thickest walls. Note that although build envelope is one of the first things listed on a 3d printer spec sheet, this doesn’t mean any part that fits in the envelope should be printed. In addition, some technologies can print thick parts but only with tradeoffs in material properties. It is important to be specific in the diligence of how each metal AM technology fits the part size and thickness requirements of an application.

Geometry Constraints

In addition to part size, there are other geometry constraints that are important in selecting the best metal AM solution. The two main constraints are the maximum unsupported overhang angle and trapped material. An overhang angle is the angle at which a portion of the part leans past vertical (a horizontal overhang is the most extreme example). Each process has a maximum overhang angle, beyond which an overhanging feature can only be printed by using supports. Support structures add time, cost, and waste to the process. In addition, for internal geometries, the support structure can become trapped material: build material that cannot be removed from internal cavities that are closed or restricted. These geometry constraints impact what part shapes are possible with a given process.

If the part design can be adapted for a specific printing process, this provides additional latitude in which processes are suitable for the application. However, many early adopters wish to avoid redesigning their parts to fit with additive manufacturing process limitations.

While we have outlined the most typical criteria, there can be other application specific criteria which should be considered before selecting the best AM solution. Once all important criteria are aggregated and key parameters selected, then a comprehensive and efficient review can determine which (if any) metal AM solutions meet the requirements. There will be a future post that will present a more detailed analysis of metal AM technologies and their capabilities across all these application criteria.

The next post will discuss all the process steps involved in utilizing metal AM in production. Please leave your email below if you would like to be updated as we release future articles in our Guide to Metal Additive Manufacturing.

Please check out other posts in our blog series,

Digital Alloys’ Guide to Metal Additive Manufacturing

Learn about the technology behind our process,

Alex Huckstepp

VP Business Development

Digital Alloys is committed to providing the technology and expertise manufacturers need to use metal additive manufacturing in production — enabling them to save time, shrink costs, and produce valuable new product.